The Calomaxrail Design Process

A Calomaxrail Original Design

A project begins with you, the customer, and a desire to improve the hot drink and food offering on-board your trains.

It may be that your existing equipment is inadequate for the services you want to provide, or it could be that you are looking to compete more effectively; with a wider selection in your catering menu.

Once we have an idea of what you need, how many people you want to serve; whether you provide a trolley service or drinks from the galley; and how much space is available; we can begin to put together a proposal.

If the initial concept is what you want, we would proceed to the manufacture of “mock-ups” that can be viewed in position on the train itself and opinions sought from catering staff. If the go-ahead is given, we would complete the design and manufacture of working prototypes that can be trialled on-board; and sent for independent 3rd party testing and approvals.

Because the design and production is carried out in house, we can react quickly; and using rapid manufacturing techniques can eliminate delay.

With our wealth of experience; and using the latest CAD design, a suite of rapid manufacturing machines and CNC equipment, we can turn your concept into a working prototype within weeks.

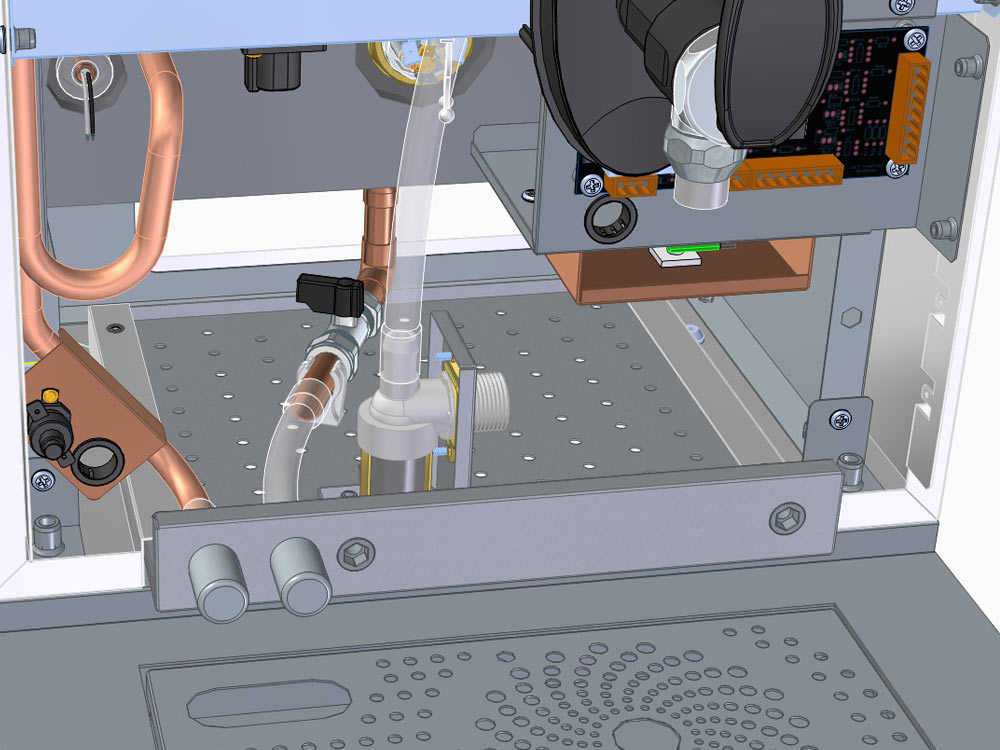

A finished boiler design for Cross Country Rail

We have 2 in-house 3D printers to aid prototyping and production

1. Original train installation

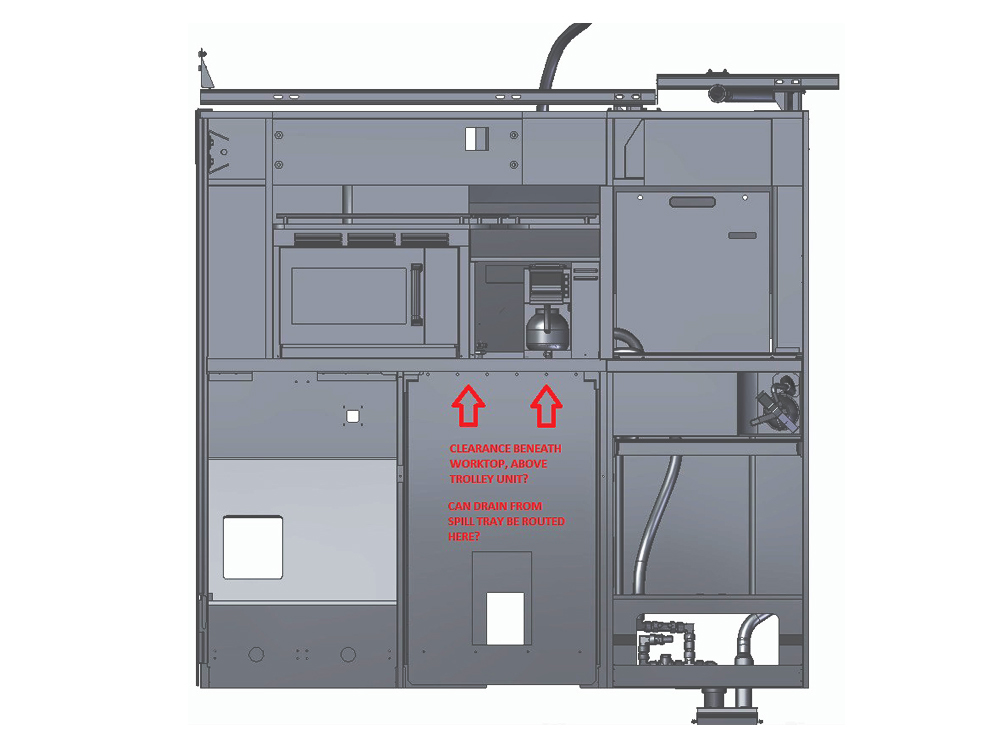

2. Initial train installation drawn up in CAD

3. CAD designs of proposed boiler

4. Internal components designed

5. Proposed boiler post revision

6. Complete train installation with a bespoke Calomaxrail boiler

Select an option below to learn more about Calomaxrail Manufacturing and Testing processes